Stage III. Life Cycle Assesment and elaboration of a business and exploitation plan in the field of manufacturing flame retardant textile materials with electromagnetic attenuation properties for Buildtech (EMFiRe)

The main results attained during Stage 3 - 2020

During the 3rd stage of the ERA-NET Manunet TexEMFiRe project, two comparative LCA studies were performed, in accordance with the provisions of the standard for LCA studies - ISO 14040, and the methodology of the dedicated ILCD Handbook, recommended by the European Commission. These studies were focused on the quantification of the environmental impact for the classical processes and the plasma coating processes involved in the manufacturing of textile screens with electromagnetic shielding (EM) and flame retardant properties.

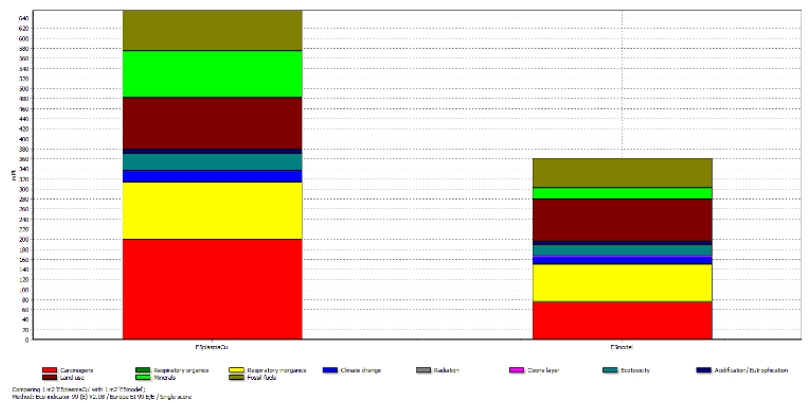

In the first study, which was a continuation of the LCA study from the 2nd stage of the TexEMFiRe project, the environmental impact was quantified for an electromagnetic screen obtained by weaving with conductive wires and a 100% textile electromagnetic screen obtained by plasma coating, using in the last case a magnetron sputtering system with improved performances (deposition rate for the copper layer of 100 nm / min), which allowed a shorter processing time and lower electricity consumption. The functional unit was set at 1 m2 textile screen with an EM attenuation of 5.2 dB for a frequency of 1 GHz. The consumptions for the conductive wire weaving process (SC Majutex SRL) and the plasma coating process (INFLPR) were identified and related to the common functional unit. Comparative environmental impact diagrams were generated during the Life Cycle Impact Assessment phase based on the ECOIndicator99 method, which includes a set of specific impact categories. In this sense, the LCA SimaPro7 software and the EcoInvent3.0 database were used.

The comparative results indicate that the impact of the magnetron sputtering installation with improved performance is at ~ 20% compared to the impact of the equipment initially used in the project.

The second LCA study quantifies the impact on the environment for a woven material with inserted conductive wires and plasma coating. It has an experimentally determined electromagnetic attenuation, between 40-55 dB on the frequency range 0.1 - 1000 MHz. This textile screen is evaluated in comparison with a modeled woven structure with conductive threads, without plasma coating, which has a similar EM attenuation in the frequency range. The distance between the conductive wires for the modeled woven structure was reduced to obtain the gain of approx. 10 dB on the frequency range, brought by the plasma coating. The functional unit was set at 1 m2 textile screen with an EM 53 dB attenuation for a frequency of 1 MHz. Moreover, the fireproofing treatment was obtained, obtained through the classic cleaning and scouring processes and respectively by plasma grafting of Apyrol process. The functional unit has been set at 1 m2 textile screen with fireproof properties.

Single score diagrama for the electromagnetic screens coated by plasma (left) and woven (right)

Single score diagrams showed an impact with a ratio of 1.8: 1 for the plasma coating process to the weaving process for the EM shielding property and an impact with a ratio of 4.1: 1 for the plasma grafting process to the process scarves for fireproofing property. The pronounced impact in the case of plasma coating processes can be explained by using laboratory facilities and obtaining small samples.

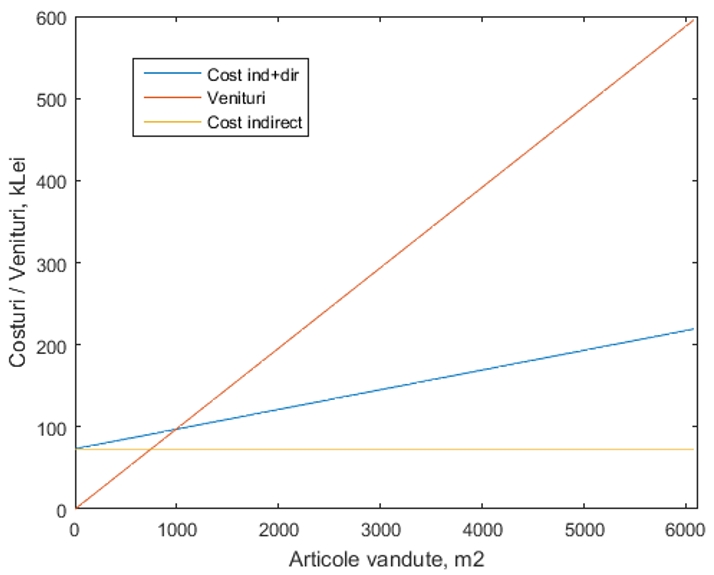

Plasma coating has multiple advantages compared to conventional processes: it does not change the properties of the textile substrate ensuring a good flexibility of the screen, and the thickness of the layer can be designed as needed. Also, the amount of residue is very limited. In order to reduce the impact on the environment, the possibility of implementing an industrial plasma installation at SC Majutex SRL was analyzed, starting from the input data obtained within the project and taking into account an investment in an industrial equipment. Based on these information, as well as all the data on the finished products that can be made and the expected sales market for them, where in particular the office space construction market was considered, a business plan was drawn up. Based on a SWOT analysis that highlights all relevant aspects, as well as economic calculations related to the amortization of the investment, the break-even point was determined at the share of 1100 items sold, ie after 4 months from the start of production and sales.

Calculation of the break even point considering as product unit 1sqm of EM shield textile screen

Based on the results obtained within the project, a national patent application was elaborated, which is to be transmitted to OSIM in the next period.

List of ISI and BDI papers

1. Conductive textile structures and their contribution to electromagnetic shielding effectiveness- Authors: RADULESCU Ion Razvan, SURDU Lilioara, MORARI Cristian, MITU Bogdana, COSTEA Marian, GOLOVANOV Nicolae - Industria Textila 5/2020, ISSN 1222–5347 (ISI)

2. Combining Fluorinated Polymers with Ag Nanoparticles as a Route to Enhance Optical Properties of Composite Materials, Veronica Satulu, Bogdana Mitu , Valentin Ion, Valentina Marascu, Elena Matei, Cristian Stancu, Gheorghe Dinescu, Polymers 2020, 12, 1640; doi:10.3390/polym12081640, https://www.mdpi.com/2073-4360/12/8/1640/pdf (ISI)

3. Influence of plasma coated woven fabrics yarn’s density on electromagnetic shielding effectiveness – Authors: RADULESCU Ion Razvan, SURDU Lilioara, VISILEANU Emilia, SCARLAT Razvan, CONSTANTIN Catalin, MORARI Cristian, MITU Bogdana – Annals of the University of Oradea, Fascicle of Textiles, Leatherwork Vol. 21, 1/2020 (BDI)

Proceedings in extenso of international conferences

1) Comparative life cycle assessment study for fabric based electromagnetic shielding, RADULESCU Ion Razvan, VISILEANU Emilia, SCARLAT Razvan, MITU Bogdana, ICAMS 2020 – 8th International Conference on Advanced Materials and Systems.

Large audience dissemination

https://www.manunet.net/images/_documents/testimonials/ManuMagazine-TexEmFire.pdf

Manufacturing textiles with electromagnetic shielding and fire retardant properties by plasma based methods

Manufacturing textiles with electromagnetic shielding and fire retardant properties by plasma based methods